Views: 0 Author: Site Editor Publish Time: 2025-10-22 Origin: Site

Transformer cores are the backbone of electrical transformers. Without them, energy transfer would be inefficient, leading to higher costs and poor performance. In this guide, we will delve into transformer cores, covering their types, construction, and purpose. You'll also learn how different core designs affect efficiency, energy loss, and application suitability.

A transformer core is the magnetic component that forms the central part of a transformer, responsible for conducting magnetic flux between the primary and secondary windings. Most transformer cores are made of laminated sheets of ferrous material, like silicon steel, that reduce eddy current losses. These laminated layers enhance the magnetic permeability and help direct the magnetic flux efficiently.

The core ensures the efficient transfer of electrical energy by focusing and amplifying the electromagnetic flux that is created when current passes through the primary winding. By doing so, the core increases the efficiency of the transformer and minimizes energy losses.

A transformer core consists of various parts that work in unison to form an efficient magnetic circuit:

● Limbs: These are the vertical components around which the windings are wrapped. They can also be referred to as legs. The limbs are vital as they carry the magnetic flux and direct it through the windings.

● Yoke: The yoke is the horizontal section that connects the limbs. It completes the magnetic circuit, allowing magnetic flux to flow continuously through the core.

The configuration of the limbs and yokes determines the transformer’s magnetic characteristics, affecting both its efficiency and performance. Different designs cater to specific operational needs, such as handling higher power levels or reducing energy losses.

Laminated cores are the most common type used in traditional transformers. These cores are made up of thin layers of silicon steel sheets stacked together. This lamination helps reduce eddy current losses, which are generated by the alternating magnetic field.

Benefits of Laminated Cores:

● Reduced Eddy Current Losses: The thin layers of steel prevent the formation of large circulating currents within the core, improving energy efficiency.

● Wide Application: Ideal for low-frequency, high-power transformers, such as those used in power transmission.

Laminated cores are especially useful in transformers that need to handle significant voltage and power levels efficiently, making them the go-to choice for many industrial transformers.

A distributed gap core, also known as a wrapped core, is designed to provide better efficiency in distribution transformers. The windings of the transformer are surrounded by a core that is built with multiple layers of metal, each separated by small gaps.

Advantages of Distributed Gap Cores:

● Faster Assembly: These cores have a simpler design that results in faster manufacturing times.

● Lower Manufacturing Costs: The core's design reduces material costs without compromising performance.

● Efficiency: Distributed gap cores typically have lower losses compared to traditional laminated cores, making them a preferred choice for distribution transformers.

These cores are mainly used in three-phase and single-phase distribution transformers, where efficiency and cost are critical.

Amorphous and nanocrystalline cores are advanced materials used in transformer construction to achieve higher energy efficiency. Amorphous cores are made from metal alloys that lack a crystalline structure, offering superior magnetic properties. Nanocrystalline materials have ultra-high permeability, making them suitable for high-frequency and energy-efficient applications.

Benefits of Amorphous & Nanocrystalline Cores:

● Lower No-Load Losses: These materials significantly reduce energy losses during the transformer’s idle time, making them ideal for energy-efficient designs.

● Enhanced Efficiency: Both amorphous and nanocrystalline cores are designed to minimize core losses, especially under low-load conditions.

● Specialized Applications: These cores are used in applications like renewable energy systems, energy storage, and high-efficiency power transformers.

While they are more expensive than traditional cores, their long-term efficiency benefits make them a preferred option for applications that prioritize energy savings.

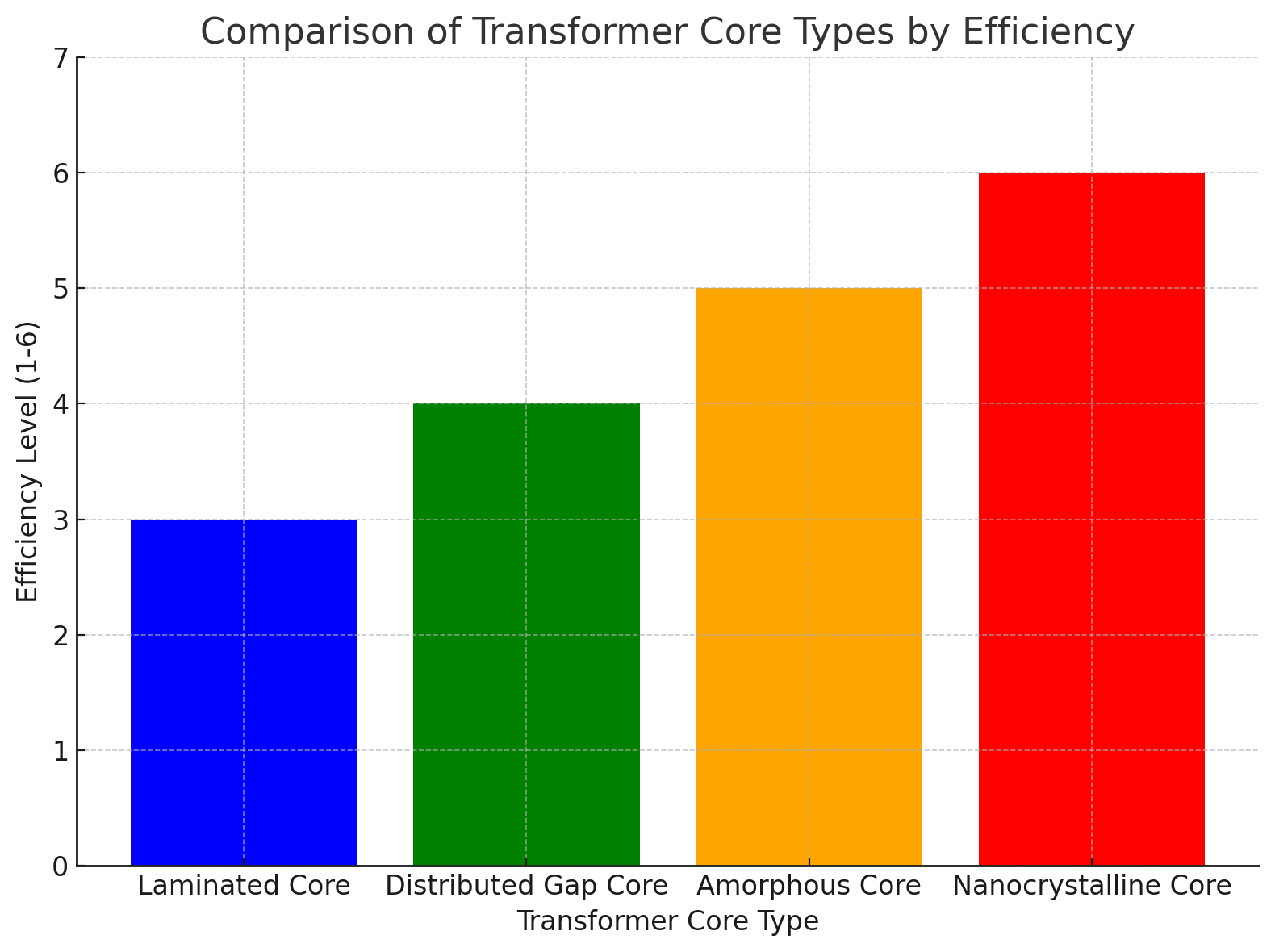

Transformer Core Type | Efficiency | Application | Cost |

Laminated Core | Moderate | Power Transformers | Moderate |

Distributed Gap Core | High | Distribution Transformers | Low |

Amorphous Core | Very High | Energy-Efficient Applications | High |

Nanocrystalline Core | Ultra-High | Specialized High-Efficiency Applications | Very High |

The materials used in transformer core construction play a vital role in determining the efficiency and performance of the transformer. Some common materials include:

● Silicon Steel: The most widely used material, silicon steel offers good magnetic permeability, reducing core losses. It comes in two forms: grain-oriented (GO) and non-grain-oriented (NGO). Grain-oriented steel is primarily used in power transformers for its high efficiency.

● Amorphous Steel: These cores have disordered atomic structures, leading to ultra-low energy losses, especially beneficial for distribution transformers.

● Nanocrystalline Materials: Known for their extremely high permeability and low losses, these materials are used in high-efficiency transformers for specialized applications.

The manufacturing process significantly influences the performance of transformer cores. Key processes include:

● Cold Rolling: Silicon steel is cold-rolled to increase its strength and improve magnetic properties. Cold rolling also reduces the thickness of the steel, enhancing the transformer’s efficiency.

● Annealing: This process involves heating the material to remove impurities and increase its ductility, making it easier to work with and improving its magnetic properties.

● Grain Orientation: In grain-oriented steel, the grain structure is aligned to enhance magnetic flux, reducing losses and improving efficiency.

These processes are essential for ensuring that the core material performs optimally in the transformer.

Transformer cores can be assembled in different configurations, primarily shell-type and core-type.

● Shell-Type: In this configuration, the core surrounds the windings, creating a closed-loop path for magnetic flux. This design is preferred in high-current applications as it provides better short-circuit protection and lower leakage reactance.

● Core-Type: In this configuration, the windings are placed around the core, leaving the flux path open. This design is typically used in power transformers due to its simplicity and ease of cooling.

Material | Magnetic Permeability | Energy Loss | Durability |

Silicon Steel | High | Moderate | Good |

Amorphous Steel | Very High | Low | High |

Nanocrystalline Alloy | Ultra-High | Minimal | Very High |

Core losses, including hysteresis losses and eddy current losses, directly impact the efficiency of a transformer. Proper core design minimizes these losses, allowing transformers to operate more efficiently.

● Hysteresis Losses: Caused by the lagging of the magnetic field behind the applied voltage, hysteresis losses can be reduced by using high-quality, low-hysteresis materials like grain-oriented silicon steel.

● Eddy Current Losses: These are minimized by using laminated cores, which prevent large circulating currents from forming within the material.

Tip: To maximize transformer efficiency, invest in high-quality core materials and design that minimize both hysteresis and eddy current losses.

The material chosen for the core directly impacts the efficiency of energy transfer. For example:

● Silicon Steel is cost-effective and widely used for its good magnetic properties.

● Amorphous Steel offers lower losses but at a higher cost, ideal for applications requiring low no-load losses.

● Nanocrystalline Materials provide the best efficiency but are generally used in specialized, high-performance applications.

Choosing the right material based on application-specific requirements is crucial for ensuring optimal efficiency and cost-effectiveness.

Core design must be tailored to specific applications. For example:

● Power Transformers: These require high-efficiency cores, such as grain-oriented silicon steel, to handle high voltage and large power transfers.

● Distribution Transformers: In these cases, amorphous and nanocrystalline cores are often used to reduce energy losses, particularly in low-load conditions.

By understanding the energy demands and operational requirements, you can select the most suitable core material and design for your application.

The geometry of the core significantly influences its performance, especially in terms of efficiency and noise reduction. Core-type transformers have windings wrapped around the core limbs, while shell-type transformers surround the windings with the core.

● Core-Type Transformers are simpler and cost-effective, with better cooling options.

● Shell-Type Transformers provide better magnetic flux control, reduce leakage reactance, and are more robust in fault conditions.

Limb configurations affect how the transformer handles flux distribution and load balancing. Three-limb, four-limb, and five-limb designs cater to different power requirements:

● Three-Limb Cores: Common in medium-voltage transformers, they are compact and cost-effective but may be less suitable for complex load configurations.

● Four-Limb Cores: Offer better load balancing and are ideal for transformers with asymmetrical loads.

● Five-Limb Cores: Provide the best stability and are used in high-load industrial applications where reliability is crucial.

Choose a limb configuration that matches your transformer's power rating and load requirements to ensure optimal performance.

The design of the core geometry determines how magnetic flux flows through the transformer. A well-designed core ensures that magnetic flux remains concentrated, reducing losses and improving efficiency.

Minimizing magnetic flux leakage by optimizing core design is key to reducing energy loss and improving transformer lifespan.

Amorphous and nanocrystalline cores are often used in renewable energy applications, such as solar and wind power, to enhance energy savings and efficiency. These cores offer low no-load losses, which are crucial for intermittent power sources.

For applications like electronics and switch-mode power supplies (SMPS), ferrite and nanocrystalline cores are favored. Their high permeability and low eddy current losses make them ideal for high-frequency operations.

In industrial settings, five-limb cores made from high-strength materials provide superior reliability and performance under heavy loads. These are used in high-power transformers where stability and fault tolerance are critical.

Choosing the right core material depends on your transformer's load demands and efficiency goals. For high-load applications, select materials with high magnetic permeability, such as grain-oriented silicon steel.

While advanced core materials like amorphous and nanocrystalline alloys offer superior performance, their higher cost may not always be necessary. Balance material cost with long-term energy savings for optimal investment.

Reliability is crucial for transformers, especially those used in critical infrastructure. Opt for cores designed with durability in mind, considering factors like insulation, cooling systems, and fault resilience.

Transformer cores play a critical role in efficient energy transfer and transformer performance. Choosing the right material and design ensures optimal efficiency, reduces losses, and minimizes operational costs. Whether for power transmission, renewable energy, or industrial use, selecting the proper core is essential. Shanghai JISCO offers high-quality transformer cores that provide superior performance and durability, helping clients meet energy efficiency standards and reduce long-term costs.

A: A transformer core is the central part of a transformer, made of laminated sheets of ferrous material. It facilitates the efficient transfer of energy by focusing the magnetic flux between the primary and secondary windings.

A: The transformer core plays a key role in enhancing energy transfer and minimizing losses. It ensures that magnetic flux flows efficiently, reducing energy wastage and improving transformer performance.

A: Different materials like silicon steel, amorphous steel, and nanocrystalline alloys influence energy loss, efficiency, and durability. Each material is chosen based on the specific transformer application to maximize performance.

A: Transformer cores are mainly categorized into laminated, distributed gap (wrapped), and amorphous cores. Each type is selected based on the transformer’s power, efficiency needs, and application.

A: The design of the transformer core, such as using laminated or amorphous materials, affects the noise level. Proper design minimizes magnetostriction and vibrations, reducing transformer hum.

A: When selecting a transformer core, consider the material, core design, load capacity, and energy efficiency requirements to ensure optimal performance and cost-effectiveness for your specific application.

A: Transformer core efficiency can be improved by choosing materials with high permeability, reducing core losses through lamination, and optimizing core geometry to reduce flux leakage and energy loss.