Views: 0 Author: Site Editor Publish Time: 2025-10-30 Origin: Site

Electrical transformers are essential for efficient electricity distribution. At the heart of each transformer is the crucial transformer core. Over time, transformer core designs have evolved to meet higher efficiency demands. In this article, we’ll explore the evolution of transformer core technology, from its humble beginnings to modern innovations in materials and manufacturing.

The history of electrical transformers dates back to the late 19th century, where they began with simple designs using iron cores. These early transformer cores were made of solid iron, which was efficient in generating the magnetic fields required for energy transfer. However, these cores had significant limitations, including energy losses due to hysteresis and eddy currents.

As power demands grew, engineers realized the need to refine the design for better efficiency. The initial challenges lay in the balance between core material, size, and power output. These early designs, though revolutionary, were often inefficient and large, making them impractical for many applications.

The concept of transformer cores can be traced back to Michael Faraday's groundbreaking discovery of electromagnetic induction in 1831. Faraday's experiment demonstrated how a changing magnetic field could induce a current in a nearby conductor, laying the foundation for the development of electrical transformers. The early transformer cores, constructed from iron, were essential in creating a magnetic circuit, which allowed for the induction of power from one coil to another. These initial cores, while rudimentary, were essential for the later development of more efficient designs.

The use of iron in the cores continued for several decades. However, as researchers discovered the limitations of pure iron, they began experimenting with steel, which had better magnetic properties, though still insufficient to reduce energy losses. This experimentation paved the way for later, more advanced materials.

In 1885, engineers Ottó Bláthy, Miksa Déri, and Károly Zipernowsky from the Austro-Hungarian Empire created the Z-D-B transformer design, which used a laminated iron core. This marked a major leap in transformer efficiency. The laminated design reduced eddy currents—unwanted circulating currents in the core material—by allowing the iron sheets to be stacked with an insulating layer in between. This improvement dramatically enhanced transformer performance, making it possible to transfer electrical energy over longer distances without as much energy loss.

The Z-D-B transformer was the precursor to modern transformer designs, influencing the direction of electrical transformer technology for years to come. It also highlighted the importance of improving the transformer core material to enhance efficiency.

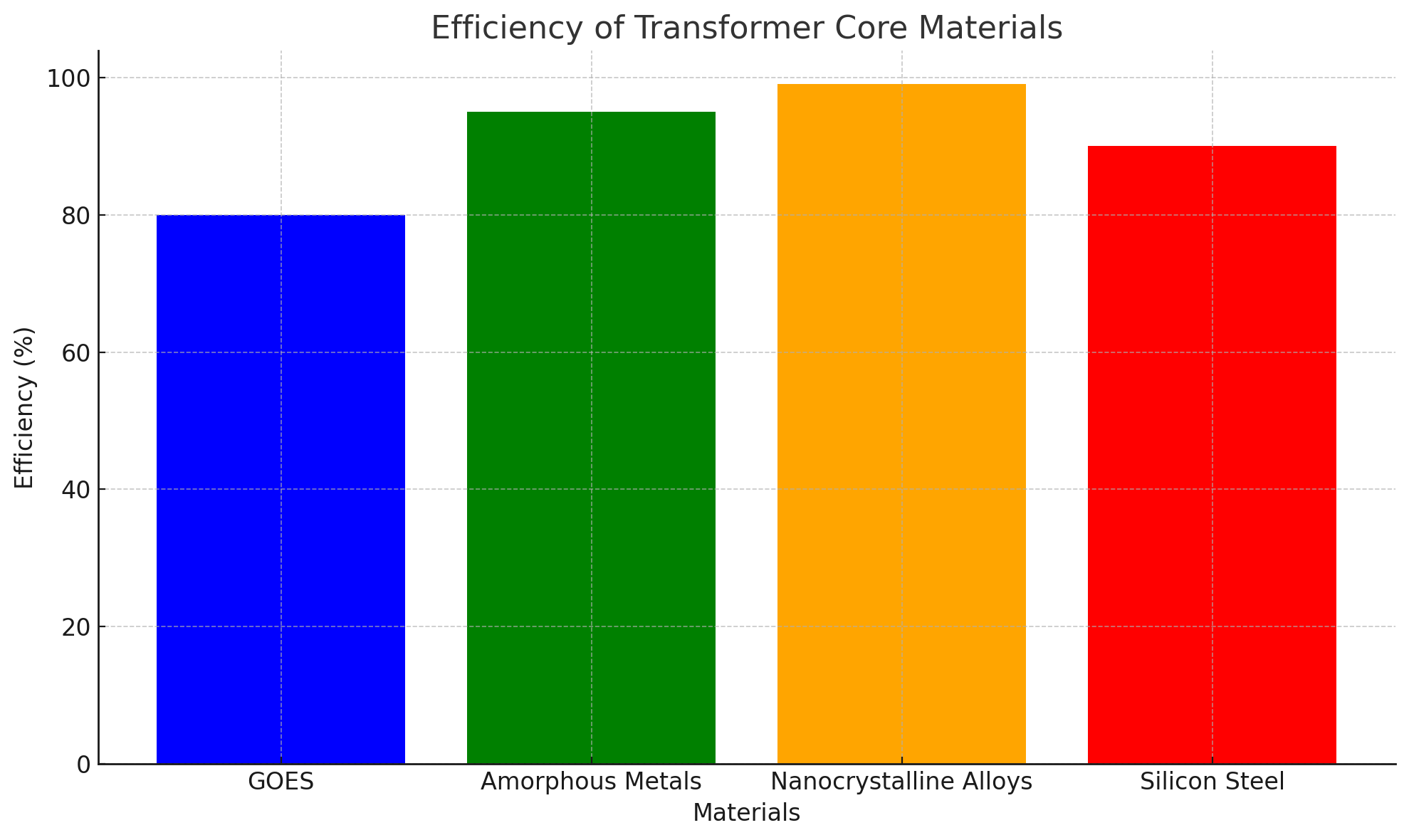

The mid-20th century saw a significant leap in transformer core materials with the introduction of grain-oriented electrical steel (GOES). Unlike traditional steel, GOES is processed to align its grains in a specific direction, which maximizes its magnetic properties. This orientation helps to reduce energy loss caused by hysteresis and eddy currents, making GOES a key material in high-efficiency transformers.

The development of GOES provided a major boost to transformer performance, especially in high-power applications. As the demand for electrical power continued to grow, engineers increasingly relied on GOES to improve transformer reliability and reduce the overall cost of energy transmission.

In the search for even more efficient materials, scientists began to experiment with amorphous and nanocrystalline alloys. These materials have unique magnetic properties that make them ideal for transformer cores. Amorphous metals, in particular, are made by rapidly cooling molten material to prevent the formation of a crystalline structure, resulting in a metal that has lower core losses.

Nanocrystalline alloys are even more advanced, with a finely structured grain arrangement that enhances magnetic permeability and reduces energy losses to a minimum. These materials are particularly beneficial for applications that require low core loss and high energy efficiency, such as in transformers used for renewable energy systems.

Silicon steel, or electrical steel, has become the standard material for modern transformer cores. By adding silicon to steel, its electrical conductivity is reduced, while its magnetic properties are enhanced. This material offers a higher level of efficiency than traditional steel, making it essential for modern transformers that require minimal energy loss.

Silicon steel is particularly important in large transformers used for power transmission, as it allows the transformer core to carry large amounts of energy with minimal waste. Its high permeability ensures that the transformer can operate efficiently at both high and low frequencies, making it versatile and reliable.

Material | Magnetic Properties | Efficiency | Common Applications |

Grain-Oriented Electrical Steel (GOES) | High permeability, low core losses | High efficiency | Power transmission transformers |

Amorphous Metals | Lower core losses, higher magnetic permeability | Very high efficiency | High-efficiency transformers |

Nanocrystalline Alloys | Extremely low core losses, high magnetic saturation | Ultra-high efficiency | Advanced, compact transformers |

Silicon Steel | Moderate permeability | Improved efficiency | Common in standard transformers |

In the early days of transformer manufacturing, cores were produced manually. Workers would cut and stack iron sheets, often without the precision and automation we see today. The processes were labor-intensive, and quality control was often inconsistent. Due to the lack of precise machinery, early transformer cores were prone to inefficiencies, with air gaps between the lamination layers, which led to significant energy losses.

These early methods were also slow and costly, limiting the scale at which transformers could be produced. However, as demand for electricity grew, manufacturers sought ways to improve these processes.

With advancements in technology, the transformer core manufacturing process became more automated. Automated cutting and stacking systems allowed for greater precision, reducing air gaps and ensuring that laminations were aligned properly. This increased the consistency and efficiency of transformer cores, leading to higher performance and reduced core losses.

Modern manufacturing facilities use computer-controlled machines to cut and stack transformer cores with exceptional accuracy. This automation has drastically reduced labor costs and improved production rates, while ensuring that transformer cores meet high-quality standards.

As transformer design and manufacturing continued to evolve, innovations in lamination stacking and loss measurement became crucial. The stacking process has been refined to minimize the formation of air gaps, which reduces the resistance of the magnetic path and lowers energy loss. Advanced lamination stacking techniques such as step-lap and mitred joints have been developed to improve transformer core efficiency.

Furthermore, measuring core losses with high precision is now a standard part of the manufacturing process. Modern measurement techniques allow for the accurate evaluation of magnetic losses in the core, ensuring that each transformer operates at its peak efficiency before it leaves the factory.

In the modern era, computer-aided design (CAD) has revolutionized the way transformer cores are designed. CAD allows engineers to create highly detailed and accurate 3D models of transformer cores, optimizing the geometry for maximum efficiency. By simulating magnetic fields and testing different core configurations virtually, CAD ensures that the final product will perform at its best before physical production begins.

CAD software also speeds up the design process, allowing manufacturers to quickly adapt to changing customer requirements or regulatory standards. This has been particularly important in industries that demand custom transformers for specific applications.

As the energy sector moves toward more intelligent systems, transformer cores are being integrated with smart technologies and Internet of Things (IoT) devices. Smart transformers equipped with sensors and communication technologies can monitor their own performance in real time. These devices can track parameters such as temperature, load, and efficiency, providing valuable insights into transformer health and enabling predictive maintenance.

The integration of IoT in transformer cores allows for better monitoring and control, reducing downtime and improving the overall reliability of electrical grids.

The push for sustainability in manufacturing has also impacted transformer core production. As industries seek to reduce their carbon footprint, transformer manufacturers are exploring more environmentally friendly materials and processes. This includes using recycled materials for core construction and adopting energy-efficient manufacturing methods.

Many modern transformers are designed to be more energy-efficient, reducing waste and improving the overall sustainability of power systems. This trend towards eco-friendly manufacturing is not only driven by regulatory requirements but also by the growing demand from consumers and businesses for greener technologies.

The use of advanced materials like amorphous steel and nanocrystalline alloys presents challenges in sourcing and handling. These materials are more delicate and difficult to work with compared to traditional steel, requiring specialized equipment and expertise. Ensuring that these materials maintain their high magnetic properties throughout the manufacturing process is crucial for maintaining transformer efficiency.

While high-efficiency transformer cores are essential for reducing energy losses, they can also be more expensive to produce. Manufacturers must balance the desire for top-tier materials with the need to keep production costs competitive. This often requires choosing the right materials for specific applications, ensuring that the benefits of efficiency outweigh the additional costs.

Precision in slitting, cutting, and stacking is crucial for maintaining the quality of transformer cores. Even small variations in the size or alignment of laminations can lead to increased core losses. Modern manufacturing techniques have drastically improved the precision of these processes, but maintaining this level of accuracy remains a key challenge for manufacturers.

As countries around the world implement stricter energy efficiency standards, transformer manufacturers are increasingly required to produce low-loss transformer cores. Regulations like the Energy Efficiency Directive in Europe and similar initiatives in the U.S. and Asia are driving the adoption of more efficient transformer technologies.

These regulations aim to reduce energy consumption and decrease the environmental impact of electrical systems. Manufacturers must ensure that their transformer cores comply with these standards while continuing to innovate for improved efficiency.

The growing shift towards renewable energy is also influencing transformer core development. Transformers play a vital role in integrating renewable energy sources like solar and wind into power grids. To handle the variability and fluctuations of renewable power, transformer cores must be designed for maximum efficiency under dynamic loads.

Renewable energy projects often require customized transformer solutions, prompting manufacturers to offer more flexible core designs that meet the specific demands of these projects.

As industries demand more specialized and efficient transformer solutions, the need for customizable transformer cores is increasing. From power transmission to distribution and industrial applications, companies are seeking transformers that can be tailored to their exact specifications. This has led to an increase in demand for manufacturers who can offer flexible and highly specialized core production.

The future of transformer cores lies in the continued development of advanced magnetic materials. Researchers are exploring new alloys and composites that offer even lower core losses and better magnetic properties. These materials could help create smaller, more efficient transformers that can handle larger power loads while minimizing energy waste.

3D printing and additive manufacturing are poised to revolutionize transformer core production. These technologies enable the creation of highly complex and customized core designs that were previously impossible with traditional manufacturing methods. This could lead to more efficient transformer cores with optimized geometries and reduced material waste.

As smart grid technologies continue to evolve, the demand for intelligent transformers will grow. These transformers will require advanced core materials that can handle high data processing and monitoring capabilities. The integration of sensors and IoT devices will require transformer cores to be both electrically efficient and capable of supporting digital technologies.

The evolution of transformer core manufacturing has been driven by the need for greater efficiency, sustainability, and adaptability. From basic iron cores to advanced nanocrystalline alloys and smart technologies, significant progress has been made. As the energy landscape shifts, manufacturers must adapt to emerging trends and regulatory changes. Shanghai JISCO continues to lead with innovative transformer core solutions, ensuring high efficiency and sustainability. Their products support the growing demand for renewable energy integration, making them vital for the future of electrical power systems.

A: A transformer core is a key component in electrical transformers. It facilitates the magnetic flux that allows electrical energy to be transferred between coils. The core plays a critical role in minimizing energy loss and improving transformer efficiency.

A: Transformer core manufacturing has evolved from manual processes using iron to advanced techniques with materials like grain-oriented electrical steel, nanocrystalline alloys, and amorphous metals, improving efficiency and reducing energy losses.

A: Modern transformer cores are primarily made from grain-oriented electrical steel (GOES), amorphous metals, and nanocrystalline alloys, offering improved magnetic properties and reduced energy losses.

A: Efficiency in transformer core manufacturing reduces energy loss, which directly impacts power transmission and reduces operational costs. Advanced materials and precision manufacturing methods ensure that transformers operate with minimal energy waste.

A: Silicon steel enhances the magnetic permeability of transformer cores, reducing core losses and increasing efficiency. It is widely used for high-performance transformers, ensuring better power handling and reliability.

A: The materials used in transformer cores, like nanocrystalline alloys and silicon steel, directly influence energy efficiency. These materials minimize core losses, improving the overall performance and sustainability of electrical systems.