Views: 0 Author: Site Editor Publish Time: 2025-06-05 Origin: Site

Transformers are essential components in electrical systems, tasked with converting voltage levels to ensure the efficient transfer of electrical energy. At the heart of every transformer are two critical components—the transformer core and transformer coils. These components work in tandem to ensure the effective transformation of electrical energy, and their design, materials, and maintenance are key to ensuring optimal performance.

The Dry Type Transformer Core, in particular, has become increasingly popular due to its safety, efficiency, and minimal maintenance needs, especially when compared to oil-immersed transformers. In this article, we will explore the function of transformer cores, common issues that arise with these components, and the repair techniques that help restore and maintain transformer efficiency.

A transformer core is a magnetic element at the center of a transformer that serves to transfer electrical energy from the primary winding to the secondary winding through electromagnetic induction. It provides a low-resistance path for magnetic flux, ensuring the efficient transfer of energy between the windings.

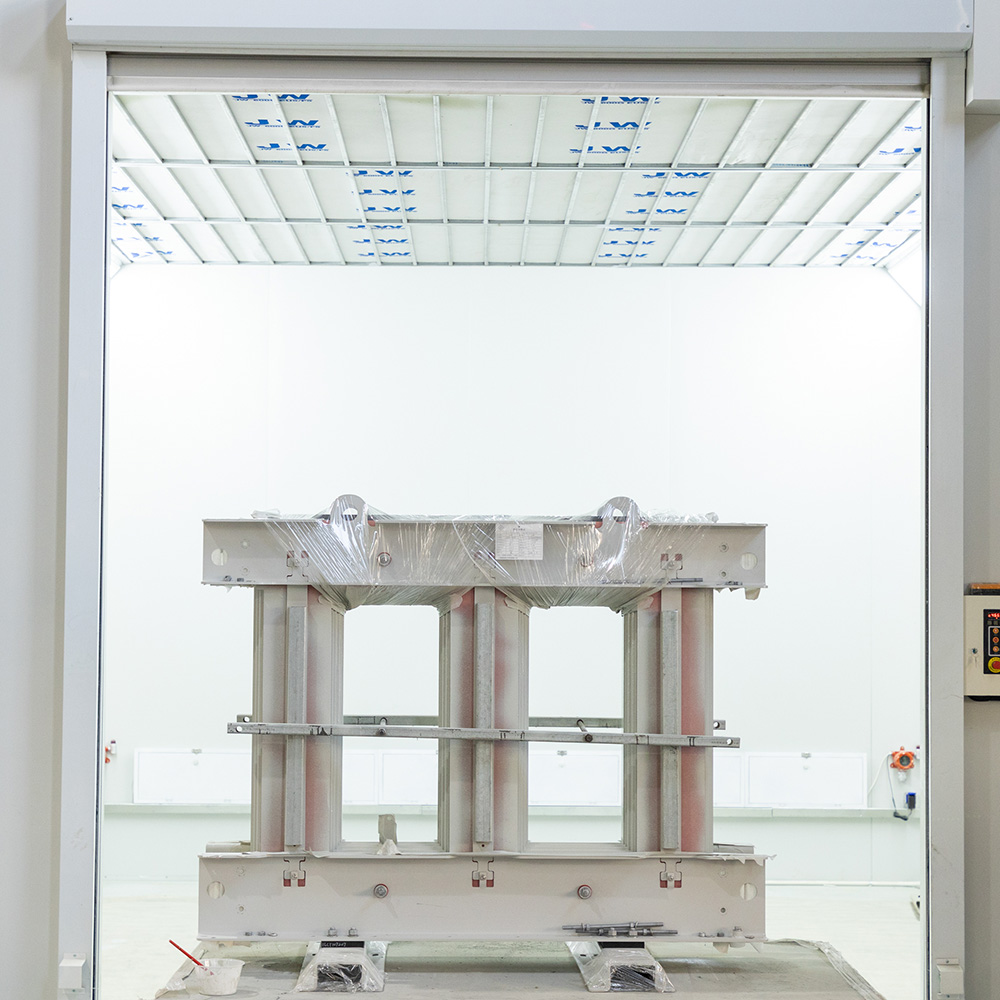

The Dry Type Transformer Core is commonly used in transformers that do not require oil-based cooling systems. Instead, these transformers use air or natural convection for cooling. Dry Type Transformer Cores are ideal for indoor environments, where safety concerns such as oil leakage or fire hazards are critical.

The core of a transformer is responsible for guiding magnetic fields between the primary and secondary coils. This process is essential for stepping up or stepping down the voltage. Transformer cores ensure that energy is transferred with minimal loss, and the design of the core plays a vital role in minimizing heat generation and energy wastage.

The material used in transformer cores plays a significant role in their performance. Common materials like silicon steel and amorphous metals offer high magnetic permeability, which allows them to conduct magnetic flux with minimal resistance. These materials also help reduce the core's energy losses due to eddy currents and hysteresis losses.

Despite their importance, transformer cores can experience various issues that affect performance and efficiency. Understanding these issues is vital for maintaining the longevity and functionality of transformers.

One of the most common issues with transformer cores is the degradation of the insulation between the laminations. Over time, the insulation can break down due to factors like moisture, mechanical stress, and thermal cycling. When this happens, it can lead to increased eddy currents, which generate heat and cause energy loss.

In Dry Type Transformer Cores, insulation degradation is particularly concerning because it can lead to electrical shorts and a reduction in transformer efficiency. Regular inspection and maintenance are essential to identifying and addressing these issues before they cause significant damage.

Another common problem is core looseness. This occurs when the laminations of the core become misaligned or when the mechanical stresses on the core cause it to loosen. This can lead to increased vibration and noise during transformer operation. If left unaddressed, core looseness can also result in additional energy loss and eventual damage to the core structure.

Tightening the core and ensuring it is securely mounted is crucial for preventing excessive vibrations and maintaining optimal performance.

Corrosion is another issue that can affect transformer cores, particularly in environments with high humidity or exposure to corrosive elements. Moisture or environmental contaminants can cause the steel laminations to rust, compromising the core’s structural integrity and performance. Corrosion can also lead to an increase in energy losses and a decrease in transformer efficiency.

In addition to core problems, the transformer’s coils are susceptible to several issues that can affect performance. These issues include insulation breakdown, overheating, and mechanical damage.

The insulation around the transformer coils can degrade over time due to thermal, electrical, or mechanical stresses. When insulation breaks down, it can lead to short circuits or reduced efficiency in the transformer.

Overheating is another common problem in transformer coils, typically caused by excessive current or poor cooling systems. Overheating can lead to insulation damage, coil deformation, and reduced transformer lifespan.

Coils can also experience mechanical damage due to external impacts, vibrations, or improper handling during maintenance. This can lead to structural damage and reduced performance.

Given the critical role transformer cores play in electrical systems, repairing damaged cores is essential for maintaining transformer efficiency. Several techniques are commonly used to address core issues and restore performance.

Core re-lamination involves disassembling the transformer, cleaning the laminations, and reassembling the core with new insulation materials. This technique is commonly used when the core’s insulation has degraded, or when excessive eddy currents are present due to insulation breakdown.

By restoring the core’s structural integrity, core re-lamination ensures that energy losses are minimized and that the transformer operates efficiently. This process is particularly important for Dry Type Transformer Cores, as it restores their ability to transfer energy efficiently while maintaining minimal heat generation.

Over time, mechanical stresses and vibrations can cause transformer cores to loosen. Core tightening is the process of using specialized tools to apply even pressure across the core, ensuring it remains securely in place. Tightening the core helps reduce vibrations, noise, and energy losses, improving the transformer's performance.

Regular tightening of the core is especially important in Dry Type Transformer Cores, as vibrations can cause mechanical stress that impacts the transformer’s stability.

To combat corrosion in transformer cores, several techniques can be used, including cleaning affected areas, applying anti-corrosion coatings, and replacing damaged laminations. Corrosion treatment helps restore the core’s structural integrity, ensuring that it continues to operate efficiently and effectively.

For Dry Type Transformer Cores, it’s essential to ensure that the core remains corrosion-free to avoid any reduction in performance due to structural weakening or energy losses.

Just as transformer cores require maintenance, transformer coils also need regular attention to ensure they operate efficiently. Several repair techniques can be used to address common coil issues such as insulation breakdown, overheating, and mechanical damage.

Re-insulation involves removing damaged insulation and replacing it with new, high-quality materials. This process ensures that the coils maintain their electrical integrity and reduces the risk of short circuits. Proper insulation is critical for preventing energy loss and ensuring that the transformer operates at maximum efficiency.

Coil rewinding is necessary when the coil windings become damaged or degraded. This process involves removing the old windings and replacing them with new wire, following the original winding configuration. Rewinding requires specialized equipment and expertise to ensure that the new windings are correctly installed and that the coil performs as expected.

Thermal upgrading is a process used to address overheating issues in transformer coils. This may involve improving the cooling system, using higher temperature-rated insulation materials, or optimizing the coil design. Thermal upgrading helps prevent coil deformation and insulation damage caused by excessive heat, ensuring that the transformer continues to operate efficiently.

Regular transformer maintenance is essential to ensure that both the core and coils continue to function effectively over time. By conducting routine inspections, cleaning, and testing, potential issues can be identified early and addressed before they result in costly repairs or replacements.

Inspections: Regular visual inspections of the core and coil components help identify signs of wear, corrosion, or insulation degradation.

Cleaning: Keeping the core and coils free from dirt, moisture, and debris is essential for maintaining optimal performance.

Testing: Periodic testing of transformer performance helps ensure that the core and coils are functioning as expected and that energy losses are minimized.

By implementing repair techniques such as core re-lamination, coil rewinding, and insulation replacement, transformers can be kept in optimal working condition for a longer period. Regular repairs help prevent catastrophic failures and ensure that transformers continue to meet the performance demands of electrical systems.

The Dry Type Transformer Core and its coils are essential components of electrical transformers, and maintaining them through regular inspections and repairs is crucial for ensuring the long-term efficiency and reliability of transformers. Core and coil repair techniques, such as re-lamination, tightening, and re-insulation, help restore performance and prevent energy losses. By addressing common issues early and implementing the appropriate repair methods, transformers can continue to operate efficiently, providing reliable power for electrical systems.

At Shanghai Jisco, we specialize in the design, manufacture, and maintenance of high-quality transformer cores and coils, including Dry Type Transformer Cores. Our expert solutions ensure that your transformers remain in peak condition, offering optimal efficiency and reliability. For more information or to consult with our experts, contact Shanghai Jisco today.