Views: 0 Author: Site Editor Publish Time: 2025-11-06 Origin: Site

Transformers are essential for the efficient transmission of electricity across various voltage levels. At the heart of every transformer is the transformer core, a key element in electromagnetic induction, allowing energy to flow effectively between circuits.

In this article, we will explore the core components that make up a transformer core, including its materials, laminations, and insulation. You’ll gain insight into how these components work together to enhance performance, reduce energy loss, and ensure safe operation.

A transformer core is the central component of a transformer that provides a magnetic pathway for the transfer of energy between the primary and secondary windings. When alternating current (AC) flows through the primary winding, it creates a magnetic field that induces a current in the secondary winding. The core enhances this process by offering a low-resistance path for the magnetic flux, which makes the energy transfer more efficient.

Without the core, the efficiency of the transformer would significantly drop, as the magnetic flux would dissipate into the surrounding air rather than coupling with the secondary winding. The primary function of the transformer core is to increase the amount of electromagnetic induction, which improves overall energy efficiency and reduces operational costs.

The materials used in the transformer core are critical to its performance. The most commonly used materials are silicon steel and amorphous steel.

● Silicon Steel: Silicon steel is preferred due to its excellent magnetic properties. The steel is typically laminated to reduce the effect of eddy currents, which can lead to energy losses. The higher the silicon content, the better the core’s magnetic properties, reducing losses and improving transformer efficiency.

● Amorphous Steel: This material is used for more energy-efficient transformers because it significantly reduces core losses. The molecular structure of amorphous steel is non-crystalline, which minimizes the energy wasted during each magnetization cycle. These cores are particularly useful in oil-filled power transformers or oil-filled distribution transformers where high efficiency is essential.

Material | Benefits | Common Applications |

Silicon Steel | High magnetic permeability, low energy loss | Power and distribution transformers |

Amorphous Steel | Reduced core losses, higher efficiency | Specialized transformers (e.g., energy-saving applications) |

Nanocrystalline Steel | High thermal stability, low core losses | High-frequency transformers, renewable energy systems |

One of the most crucial components of a transformer core is the laminated steel sheets. These sheets are stacked together to form the core, with each sheet being thinly coated with an insulating material. The purpose of this lamination is to reduce the eddy current losses that would otherwise occur in a solid metal core.

Eddy currents are small circular currents that flow within the core material, generating heat and reducing transformer efficiency. By using thin laminations, the flow of these currents is restricted, allowing the magnetic flux to travel more efficiently through the core.

Laminated cores are typically used in dry-type transformer cores and oil-filled power transformer cores to minimize energy losses and improve the overall performance of the transformer.

To prevent eddy currents and enhance the efficiency of the transformer core, the steel sheets are coated with thin insulating layers. These insulating materials, which can be made of paper, varnish, or resin, help to ensure that the magnetic flux is properly contained within the core and does not leak out.

The insulating materials also help to prevent short circuits between the laminations, which could cause transformer failure. Additionally, insulation is crucial for ensuring the longevity of the transformer core, as it helps to prevent damage from overheating or electrical breakdowns.

Component | Function | Material Used | Impact on Efficiency |

Laminated Steel Sheets | Reduces eddy current losses | Silicon steel, amorphous steel | Enhances energy efficiency |

Insulating Materials | Reduces energy loss due to circulating currents | Paper, resin, varnish | Reduces operational costs |

Windings | Transfers electrical energy between circuits | Copper or aluminum wire | Improves power transfer |

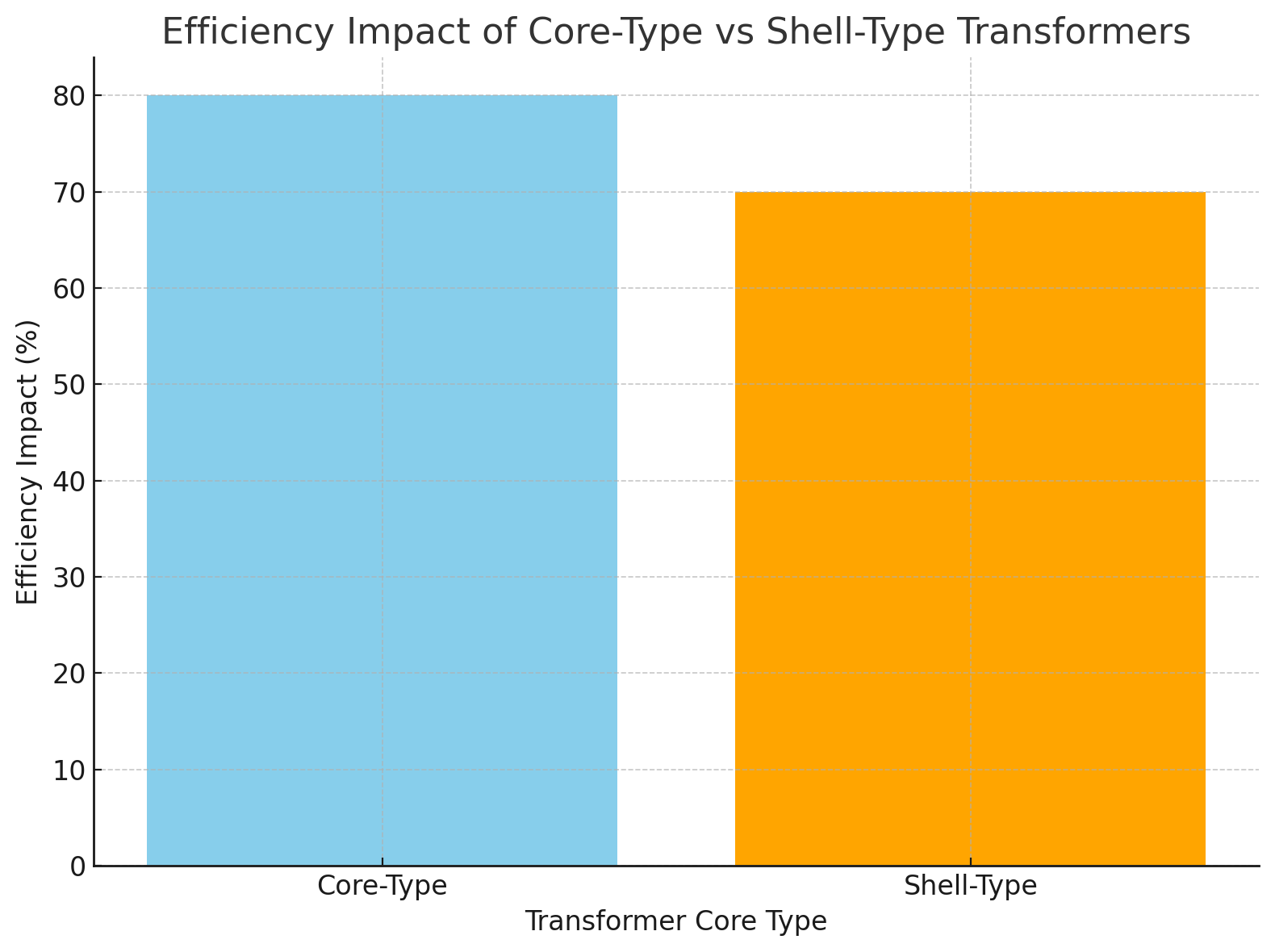

Core-type transformers are the most common design used in power transformers. In this type of transformer, the core surrounds the windings, with the magnetic flux passing through the core in a closed loop. This design allows for better coupling between the windings and the core, resulting in higher energy transfer efficiency.

The core-type design is particularly well-suited for high-voltage transformers, where maximizing energy efficiency and minimizing core losses are critical. These transformers are typically used in power transmission and distribution systems, where large amounts of energy need to be transferred across long distances.

Type | Design Description | Efficiency Impact | Common Usage |

Core-Type | Core surrounds the windings | Enhances magnetic flux, lower losses | High-voltage transformers |

Shell-Type | Windings surround the core | Better for high-frequency performance | Power transformers, industrial use |

In shell-type transformers, the windings surround the core, creating a magnetic flux path that flows through the windings first, before passing through the core. This design is often used in situations where the transformer needs to handle high loads and high voltages, as the core is designed to handle more substantial magnetic flux. Shell-type transformers also provide better protection against external interference and mechanical stresses, making them ideal for industrial applications.

Both core-type and shell-type designs are used in a variety of oil-filled power transformer cores and oil-filled distribution transformer cores. The design choice depends on factors such as the transformer’s intended use, the amount of power it needs to handle, and its size.

The windings of a transformer consist of coils of wire that are wound around the transformer core. The primary winding is connected to the input voltage source, while the secondary winding is connected to the output load. The interaction between the windings and the transformer core is what enables energy to be transferred efficiently from the primary to the secondary circuit.

The number of turns in each winding determines the voltage output of the transformer. The primary and secondary windings must be properly insulated to avoid short circuits and ensure safe operation.

Transformers generate significant amounts of heat during operation, which can cause damage to the core and other components if not properly managed. Insulation plays a critical role in protecting the transformer’s windings and core from electrical breakdowns, while cooling systems, such as oil cooling, help dissipate heat and maintain the transformer’s temperature at optimal levels.

● Oil Cooling: Oil-filled power transformer cores use transformer oil to dissipate heat. The oil circulates through the transformer, cooling the core and windings while providing insulation. The oil is often combined with radiators or cooling fans to further enhance heat dissipation, ensuring the transformer operates efficiently and safely.

The efficiency of a transformer is highly dependent on the design and materials used in the core. By using high-quality materials such as silicon steel or amorphous steel, transformer manufacturers can significantly reduce energy losses due to hysteresis and eddy currents.

High-efficiency cores, such as those found in oil-filled power transformer cores, help to minimize these losses and improve overall energy efficiency. This not only leads to cost savings but also contributes to a more sustainable electrical system by reducing wasted energy.

The selection of the right transformer core is essential for ensuring that the transformer performs efficiently and meets specific application needs. For instance, dry-type transformer cores are often used in environments where oil-filled transformers are impractical, such as indoor installations or areas with environmental concerns. On the other hand, oil-filled distribution transformer cores are ideal for larger systems requiring higher cooling capacity.

The core material, design, and construction must all be tailored to the transformer’s intended application, ensuring optimal performance and energy efficiency.

Regular inspections and tests are critical for ensuring the proper functioning of transformer cores. Electrical testing can identify potential issues such as insulation breakdowns, core faults, or the buildup of moisture, which can all negatively impact transformer performance.

Routine checks and preventive maintenance can help detect and address problems early, preventing costly repairs or failures.

Maintenance Task | Description | Frequency |

Core Inspections | Check for any physical damage or wear to core materials | Every 6 months |

Insulation Testing | Test insulation resistance to ensure no leakage | Annually |

Cleaning | Clean the core and windings to avoid buildup of debris | Every 3 months |

Proper cleaning is essential for maintaining the efficiency of the transformer core. Dust, debris, and moisture can accumulate on the core and windings, leading to reduced performance and potential overheating. Regular cleaning and upkeep, including the replacement of insulation and oil, ensure that the transformer operates efficiently over its lifespan.

The transformer core is a key element in ensuring efficient energy transfer and minimizing losses. Components like laminated steel sheets, insulation, and windings work together to optimize transformer performance. Selecting the right core material and design, along with regular maintenance, is essential for long-term efficiency. Shanghai JISCO provides high-quality transformer cores, offering durability and enhanced performance for various applications.

A: A transformer core is a magnetic component that facilitates the transfer of electrical energy between the primary and secondary windings of a transformer.

A: Laminated steel sheets reduce eddy current losses and enhance energy efficiency in transformer cores.

A: Transformer cores are typically made from materials like silicon steel and amorphous steel to minimize energy loss and improve efficiency.

A: Insulation materials between the core sheets reduce circulating currents, minimizing energy loss and improving transformer performance.

A: Core-type transformers surround the windings with the core, while shell-type transformers have windings surrounding the core. Each design impacts efficiency and performance.

A: A well-designed transformer core minimizes core losses, ensuring efficient energy transfer and reducing operational costs.

A: Regular inspections, cleaning, and testing are essential for ensuring the transformer core's longevity and optimal performance.